Safety must be first priority - especially for tables with electric motorized height adjustment.

Tables with electromotive height adjustment must have an automatic device to deactivate the control elements when moving the table. Reactivation of the control elements must be designed in such a way that they cannot be triggered accidentally by patients, users or third parties.

According to newest advice of BfArM, our tables are equipped with an integrated safety device (art. no. (B)1999) which deactivates the actuator atomatically after the last use.

The new integrated safety devices contain:

- Automatic device to deactivate the control elements:

This device goes into “sleep mode” 3 seconds after the last operation and can only be reactivated with a defined switching sequence, the so-called double tap - The motor of series DX1, 2000XLE, 2800XLE, 4000E and 4800E as well as the motor for height adjustment of tilt tables and heavy-load tables is equipped with a safety freewheeling clutch

Tables with electric lifting column series 6000E and 6800E are not intended to be equipped with a freewheeling motor due to the safety-related uncritical height adjustment system.

Integrated safety device

The actuator of this table is equipped with an integrated safety device to protect against unauthorised/unintentional operation. This device goes into “sleep mode” 3 seconds after the last operation and can only be reactivated with a defined switching sequence, the so-called double tap.

To “wake up” the actuator or the control unit, first press the desired direction of travel for approx. 1 second on the control element. After a short waiting time (1-2 seconds), press the desired direction of travel again and the actuator can be moved for a maximum of 30 seconds in this direction of travel.If the switching cycle of the double-tap function is not observed, the actuator cannot be operated. After 30 seconds of operation in one direction of travel, the actuator switches off and goes into sleep mode. The actuator can still be operated for up to 3 seconds after the last operation to ensure fine adjustment. Within this time window, it is possible to move in each direction of travel again for a maximum of 30 seconds. The actuator always goes into “sleep mode” automatically 3 seconds after the last operation.

Safety freewheeling clutch

The motor series DX1, 2000XLE, 2800XLE, 4000E and 4800E as well as the motor for height adjustment of tilt tables and heavy-load tables is equipped with a safety freewheeling clutch as standard:

When lowering, the motor declutches automatically if an obstacle is encountered, and the flow of power is interrupted. In other words, the active tractive force of the motor no longer acts; instead, simply the weight of the upper part of the table is applied. In the event of unforeseen entrapment, the risk of injury is significantly limited.

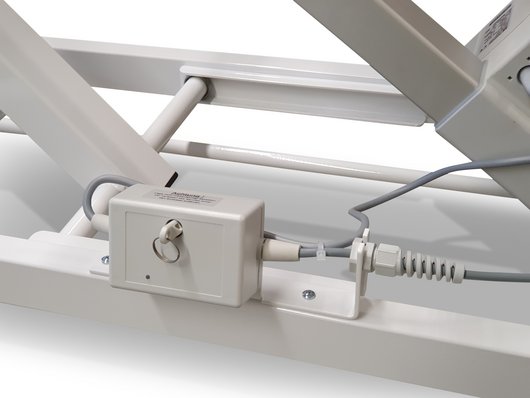

Safety box mounted at lower frame

This allows the operator to actively deactivate the table when leaving. This means that accidental operation, e. g. by unauthorised persons, is not possible and therefore cannot lead to any danger to persons.

Safety boxes have been known for many years and can also provide security by integrating them into operational processes:

When leaving and not using the table, secure it against inadvertent adjustment. Pull the magnetic pen out of the safety box. The power supply of the motor is then interrupted and adjustment is not possible.

Activate the motor by inserting the pen into the grey safety box. The power supply of the motor is now active (green LED light up) and the table can be adjusted as desired.

Art. no. (B)1993